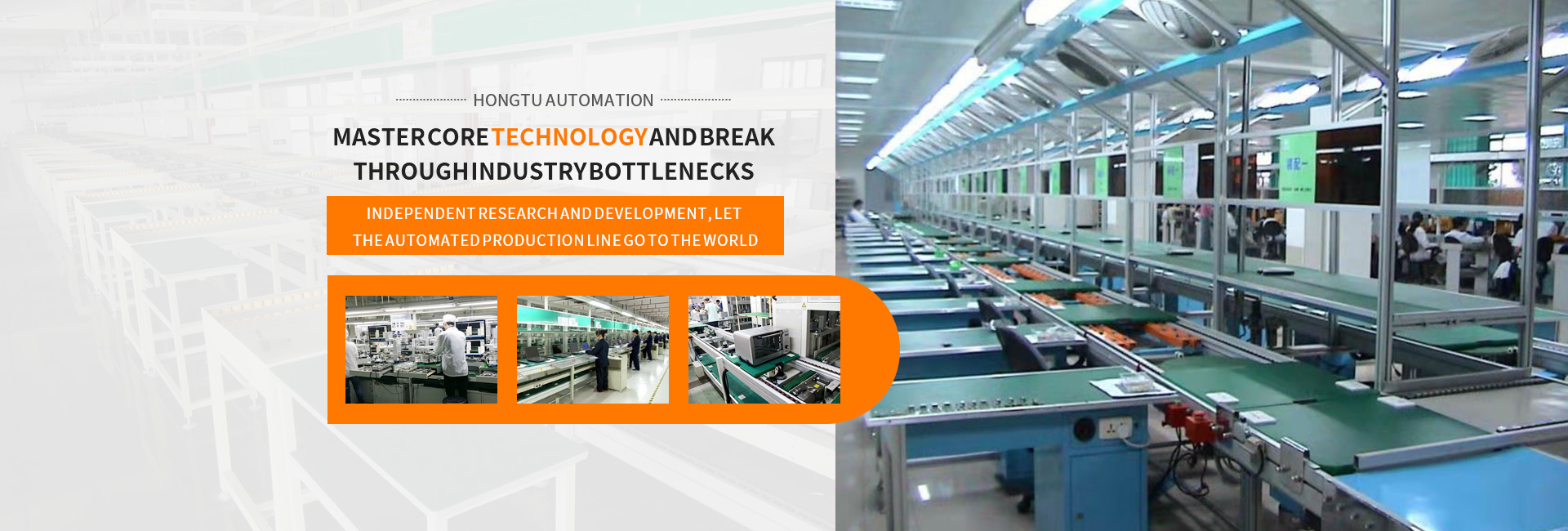

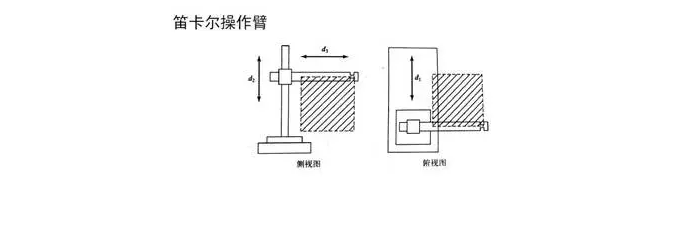

1. Cartesian operating arm

Advantages: It is easy to realize through computer control, and it is easy to achieve high precision. Disadvantages: hinder the work, and occupy a large area, the movement speed is low, and the airtightness is not good.

① Welding, handling, loading and unloading, packaging, palletizing, destacking, testing, flaw detection, classification, assembly, labeling, coding, coding, (soft copying) spraying, target following, explosion removal, etc.

②It is especially suitable for flexible operations with multiple varieties and convenient batches. It plays a very important role in stabilizing, improving product quality, increasing labor productivity, improving labor conditions and rapid product replacement.

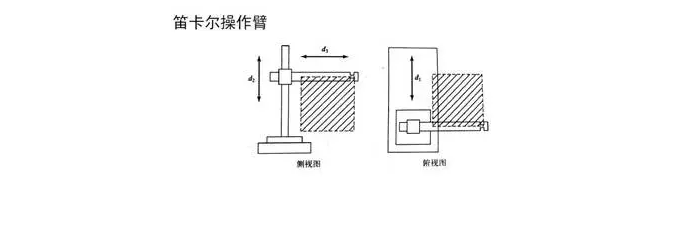

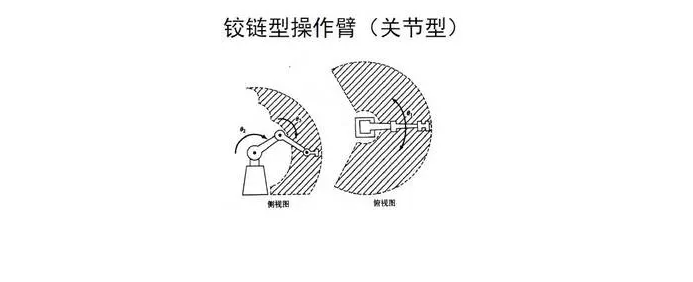

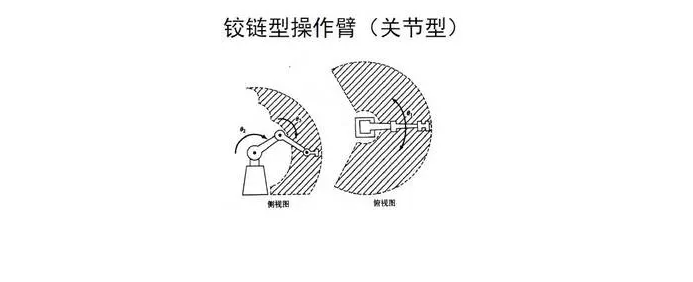

2. Hinge type operating arm (joint type)

The joints of articulated robots are all rotating, similar to a human arm, the most common structure in industrial robots. Its scope of work is more complicated.

①Rapid inspection and product development of auto parts, molds, sheet metal parts, plastic products, sports equipment, glass products, ceramics, aviation, etc.

②Three-coordinate measurement and error detection for manufacturing quality control such as body assembly and general machinery assembly.

③Rapid prototyping of antiques, artworks, sculptures, cartoon characters, portrait products, etc.

④ On-site measurement and inspection of the entire vehicle.

⑤Human body shape measurement, bone and other medical equipment production, human body shape production, medical plastic surgery, etc.

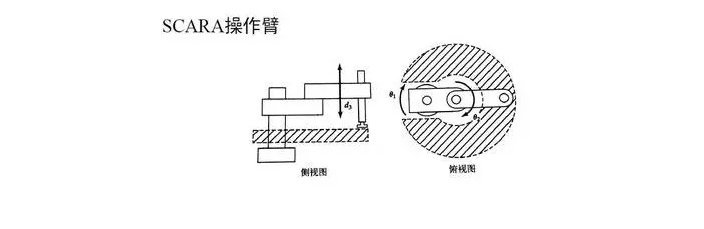

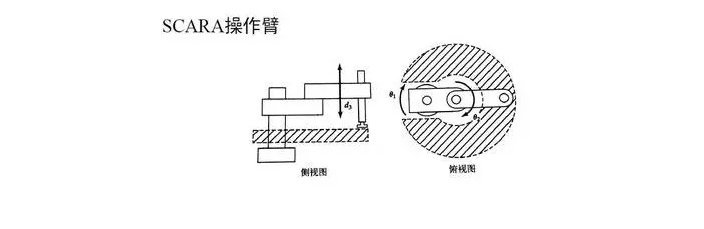

3. SCARA operating arm

SCARA robots are often used in assembly operations. The most notable feature is that their movement in the x-y plane has greater flexibility, while they have strong rigidity along the z-axis, so they have selective flexibility. This kind of robot has been well used in assembly operations.

①A large number of used to assemble printed circuit boards and electronic parts

②Move and pick and place objects, such as integrated circuit boards, etc.

③Widely used in the plastic industry, automobile industry, electronic product industry, pharmaceutical industry and food industry and other fields.

④ Removal of parts and assembly work.

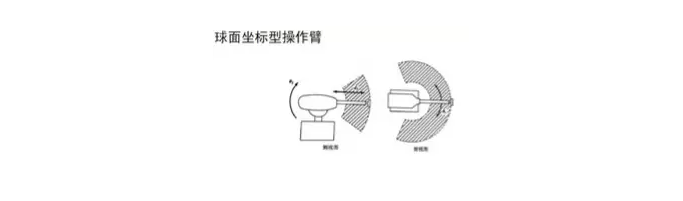

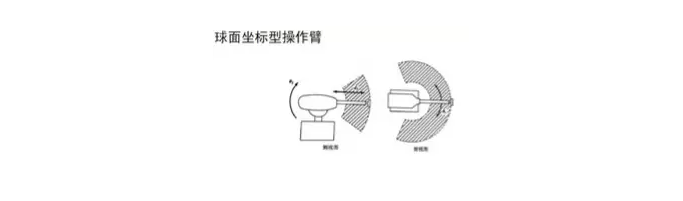

4. Spherical coordinate operating arm

Features: The working range near the center bracket is large, and the two rotating driving devices are easily sealed, covering a large working space. However, the coordinates are complicated and difficult to control, and the linear drive device has a sealing problem.

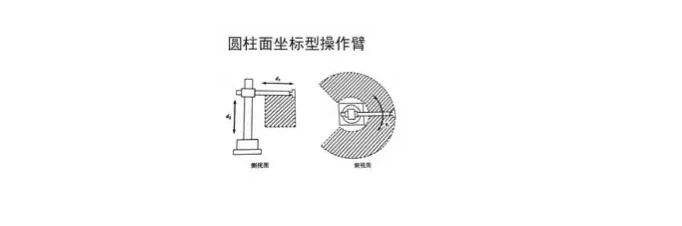

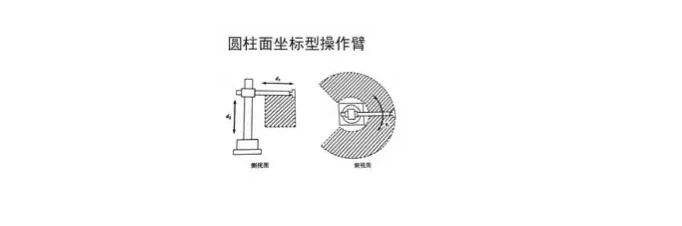

5. Cylindrical coordinate type operating arm

Advantages: and simple calculation; the linear part can be driven by hydraulic pressure, which can output larger power; can extend into the cavity of the machine. Disadvantages: The space that its arm can reach is limited, and it cannot reach the space near the column or the ground;

The linear drive part is difficult to seal and prevent dust; when the rear arm is working, the back end of the arm will touch other objects in the working range.

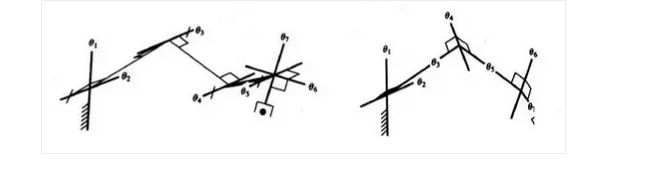

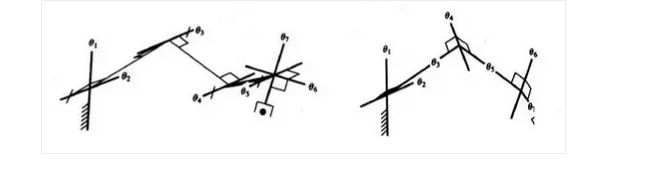

6. Redundant institutions

Usually spatial positioning requires 6 degrees of freedom, and the use of additional joints can help the mechanism avoid singularities. The figure below shows the 7-degree-of-freedom operating arm configuration

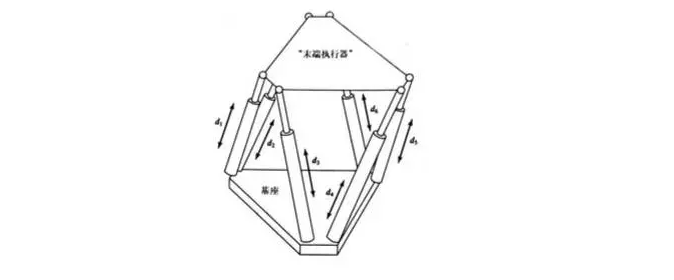

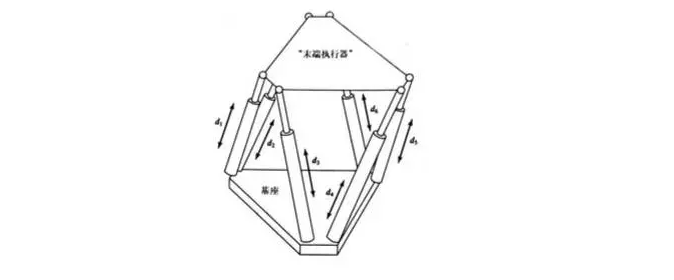

7. Closed loop structure

The closed-loop structure can improve the stiffness of the mechanism, but it will reduce the range of joint motion, and the working space will be reduced to a certain extent.

① Motion simulator;

②Parallel machine tool;

③Micro-manipulation robot;

④ Force sensor;

⑤ Cell manipulation robots in biomedical engineering can realize cell injection and segmentation;

⑥Microsurgery robot;

⑦The attitude adjustment device of the large radio telescope;

⑧ Hybrid equipment, such as SMT's Tricept hybrid manipulator module is a successful example of modular design based on parallel mechanism units.

Several common structural forms of industrial robots (pictures)

2. The main technical parameters of the robot

The technical parameters of the robot reflect the competent tasks and the highest operational performance of the robot, which are issues that must be considered in the design and application of the robot. The main technical parameters of the robot include degrees of freedom, resolution, working space, working speed, and working load.

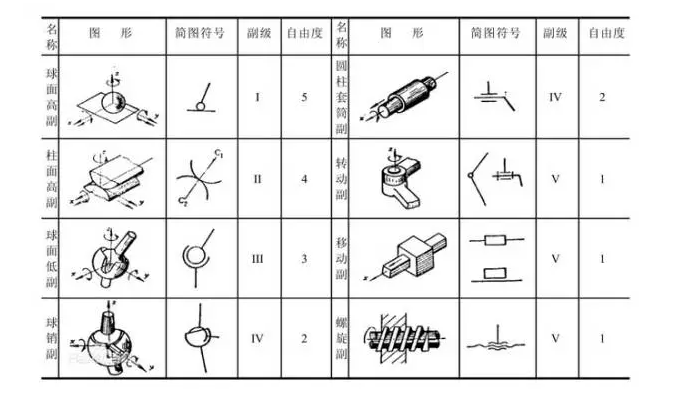

1. Degree of freedom

The number of independent coordinate axis movements that the robot has. The degree of freedom of the robot refers to the number of independent motion parameters required to determine the position and posture of the robot hand in space. The opening and closing of the fingers and the degree of freedom of the finger joints are generally not included. The number of degrees of freedom of the robot is generally equal to the number of joints. The number of degrees of freedom commonly used by robots generally does not exceed 5 to 6.

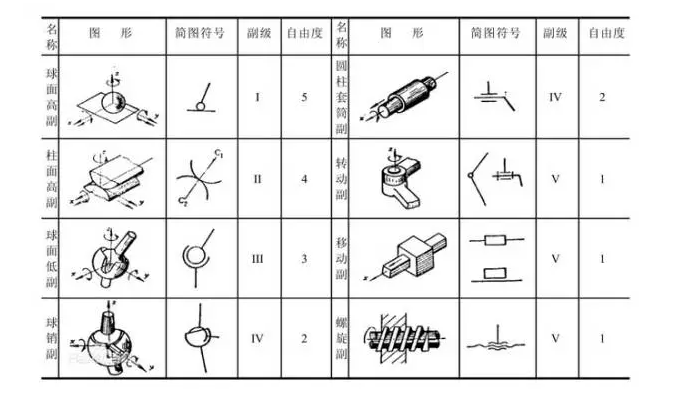

2. Joint

That is, the movement pair, the mechanism that allows relative movement between the parts of the robot arm.

3. Work space

All areas of space that the robot arm or hand installation point can reach. Its shape depends on the number of degrees of freedom of the robot and the type and configuration of each motion joint. The working space of the robot is usually represented by two methods: graphic method and analytical method.

4. Working speed

The distance or angle of rotation that the center of the mechanical interface or the center of the tool moves in a unit time of the robot under the working load condition and in the process of uniform motion.

5. Working load

Refers to the maximum load that the robot can bear at any position within the working range, generally expressed by mass, moment of inertia, and moment of inertia. It is also related to the running speed and the direction of acceleration. Generally, the weight of the workpiece that can be grasped during high-speed running is specified as an index of the carrying capacity.

6. Resolution

The minimum movement distance or minimum rotation angle that can be achieved.

7. Accuracy

Repeatability or repeat positioning accuracy: refers to the degree of difference between the robot repeatedly reaching a certain target position. Or under the same position command, the robot repeats its position dispersion several times in succession. It is a measure of the density of a list of error values, that is, the degree of repetition.

3. Commonly used materials for robots

1) Carbon structural steel and alloy structural steel. This kind of material has good strength, especially alloy structural steel. Its strength is increased by 4 to 5 times, the elastic modulus E is large, and the deformation resistance is strong. It is the most widely used material.

2) Aluminum, aluminum alloy and other light alloy materials. The common characteristics of these materials are light weight, and the elastic modulus E is not large, but the material density is small, so the E/ρ ratio can still be compared with steel. The quality of some rare and precious aluminum alloys has been more significantly improved. For example, the aluminum alloy with 3.2% (weight percent) lithium added has a 14% increase in elastic modulus and an E/ρ ratio by 16%.

3) Fiber-reinforced alloys. Such alloys, such as boron fiber-reinforced aluminum alloy and graphite fiber-reinforced magnesium alloy, have E/ρ ratios of 11.4×107 and 8.9×107, respectively. This fiber-reinforced metal material has a very high E/ρ ratio, but it is expensive.

4) Ceramics Ceramic materials have good quality, but are brittle and difficult to process. Japan has trial-produced ceramic robot arm samples for use on small high-precision robots.

5) Fiber-reinforced composite materials. This type of material has an excellent E/ρ ratio and also has a very prominent advantage of large damping. It is impossible for traditional metal materials to have such a large damping, so there are more and more examples of applying composite materials to high-speed robots.

6) Large viscoelastic damping material Increasing the damping of the connecting rod of the robot is an effective way to improve the dynamic characteristics of the robot. At present, there are many methods to increase the damping of structural materials. One of the most suitable methods for robots is to use viscoelastic large damping materials to dampen the original components.