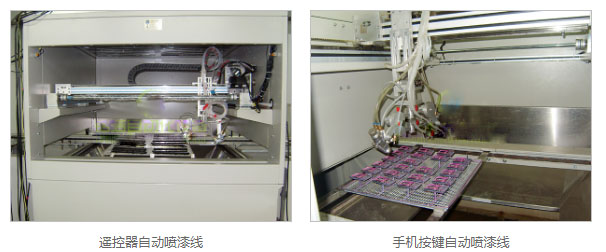

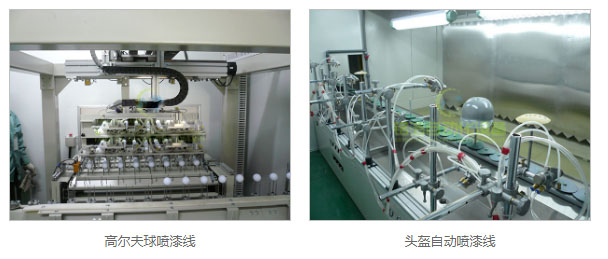

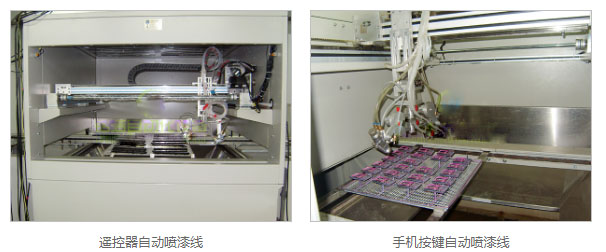

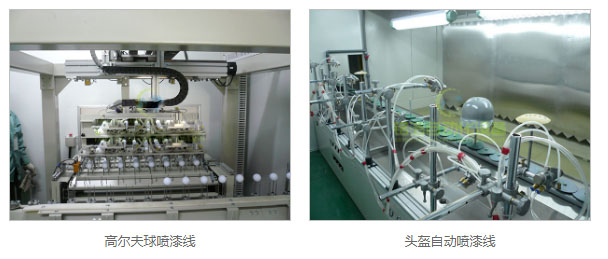

With the popularization of electronic products in people's daily work and social interactions, people have put forward higher requirements for their appearance, which requires manufacturers to have advanced production technology and processing equipment. In line with the business philosophy to meet the needs of customers, in response to various needs, Hongtu Automation has developed and developed a series of new generation dust-free products that integrate science, advancement, efficiency, economy and environmental protection according to market needs. Spraying equipment. Suitable for surface spraying of plastic parts in household appliances, electronics and general industries. (Such as mobile phones, cameras, computers, camcorders, MP3, earphones, cosmetic boxes, toys, etc.) Process flow: fixture assembly → upper part → preheating and dehumidification → automatic electrostatic dust removal before primer → automatic primer spraying → primer leveling → Primer surface drying→primer curing oven→primer cooling→automatic electrostatic dust removal before topcoat→automatic UV topcoat spraying→UV light curing→cooling section→product off shelf QC inspection

Features of plastic automatic spraying line

1. Electrostatic dust removal, spraying, drying, UV curing fully automatic assembly line operation, suitable for batch continuous production, high output, uniform coating surface.

2. Bearings are arranged at the contact point of the conveyor chain and the track, which is matched with the precise track, and it runs smoothly and smoothly without shaking.

3. Electrostatic dust removal system, imported high-voltage electrostatic generator, ion wind nozzle can be mechanically adjusted up and down, which can be changed according to the size of the product, plus the work object rotates, and there is no dead space in dust removal.

4. The automatic spray gun realizes digital mass production, replaces the traditional high-cost spray painting method, and improves the ideal production efficiency of the enterprise.

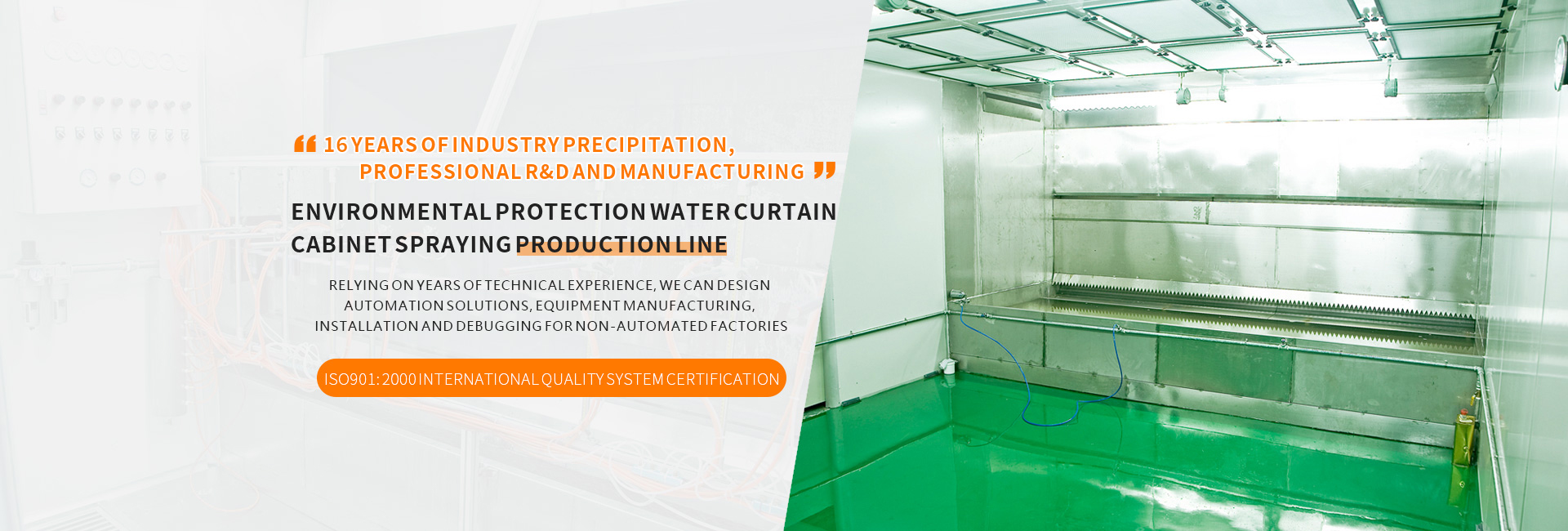

5. Water curtain environmental protection spray room design, the air flow is smooth and clean, the air deflector and spoiler in the spray room are carefully configured to keep the turbulence away from the workpiece and quickly eliminate pollution.

6. The drying room adopts a vertical hot air convection design, and the top is fully supplied with hot air. The return air from the rails can effectively suppress the pollution, and the temperature is evenly distributed. The return air is filtered by a filter and then heated for use, which is clean and energy-saving.

7. There are multiple UV lamps in the UV curing room to adjust the irradiation distance and angle arbitrarily. The forced rotation mechanism makes the workpiece get uniform irradiation with adjustable intensity. The UV lamp has an imported filter lens to prevent the workpiece from being over-irradiated and maintain the lamp tube.

Hongtu Automation can design and plan according to the production process of customers' products, tailor-made for customers, welcome new and old customers to come and order, we will serve you wholeheartedly. The company also supplies similar products to the above products: plastic automatic spray paint production line, plastic shell spray paint line, plastic parts UV automatic paint spray line, etc.